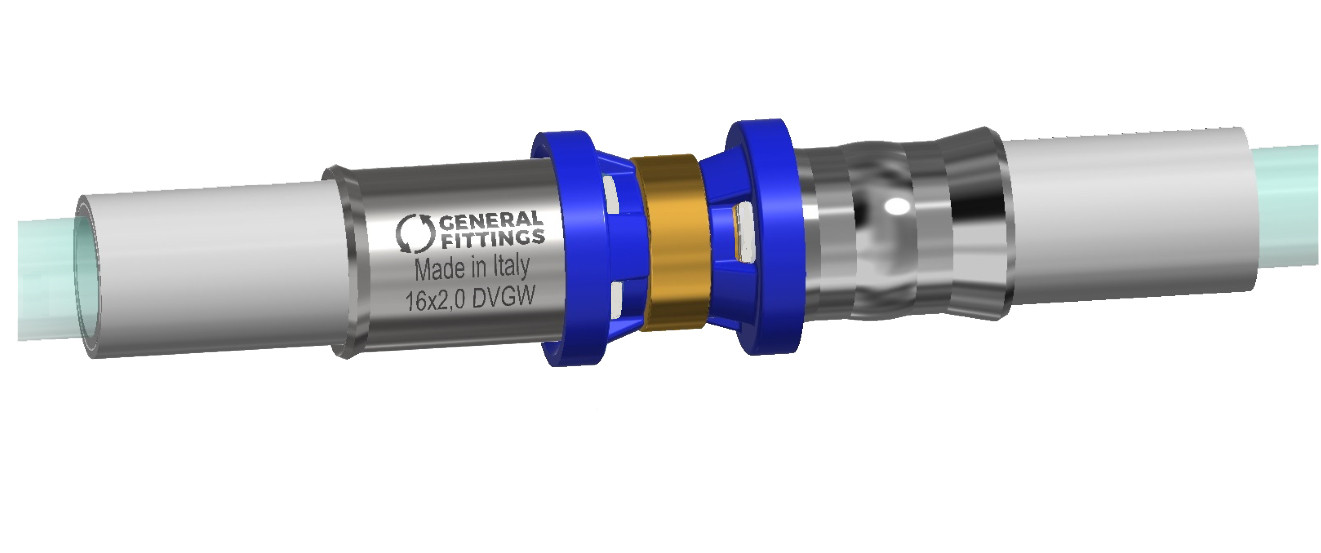

Discover Safe_Press

Advantages

Advantages

• "LEAK BEFORE PRESS” function

• Profile design for extra system safety

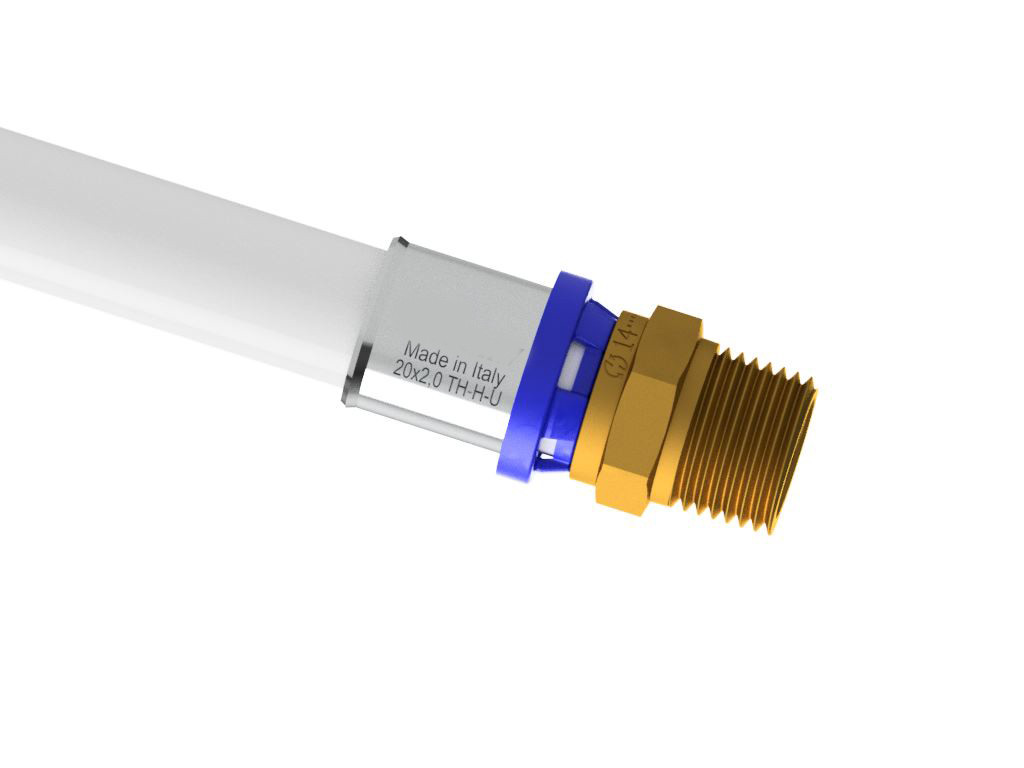

• Multitool «TH» «H «U»

• Taper threads

• Plastic insulation ring to prevent electrolytic corrosion

• Plastic compound, nylon reinforced, provide high shock resistance

even at low temperature

• Fittings made by high quality brass only complying with the

European UBA-list requirements

• Sleeves made by stainless steel AISI 304L, with annealing

treatment (1050°C).

• Granted regular deformation of the sleeve during pressing

operations.

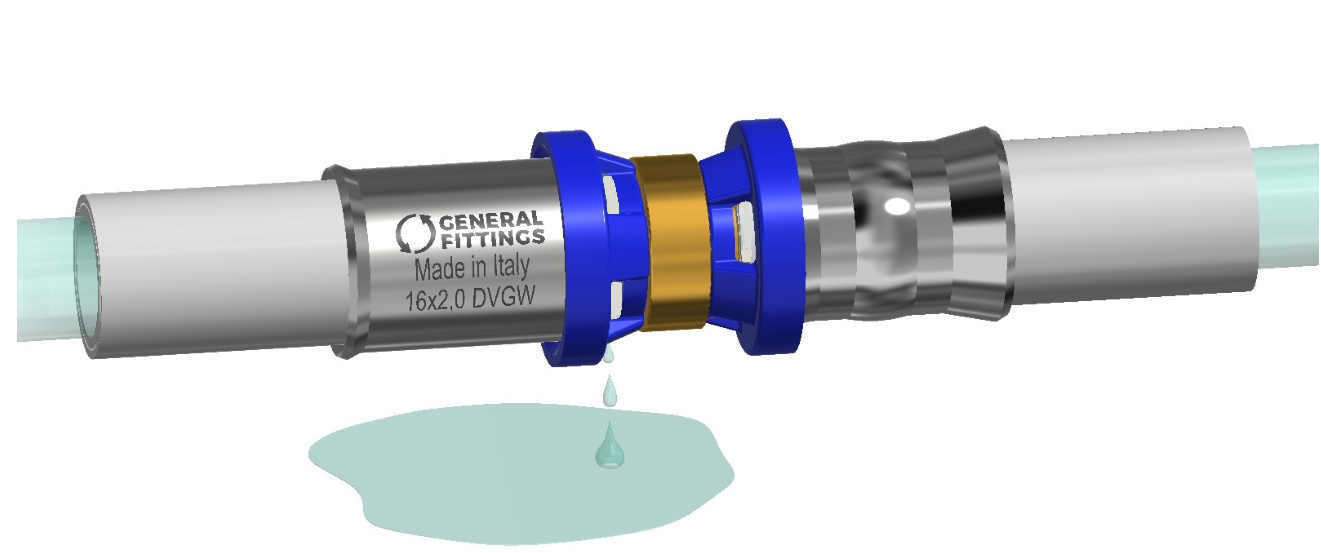

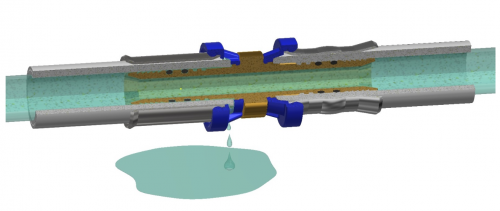

LEAK BEFORE PRESS

A skipped pressing connection is immediately detected at the leak point, even with the slightest pressure. Conclusion: the installer localizes the

leakage in order to react immediately and take precautions.

The feature “LEAK BEFORE PRESS” guarantees thus more security and time savings during the installation.

Unpressed

fitting

Right from the start with the pressure test a leakage

occurs at the unpressed connection

Pressed

fitting

The tightness of the connection is with medium flow

rate full guaranteed.

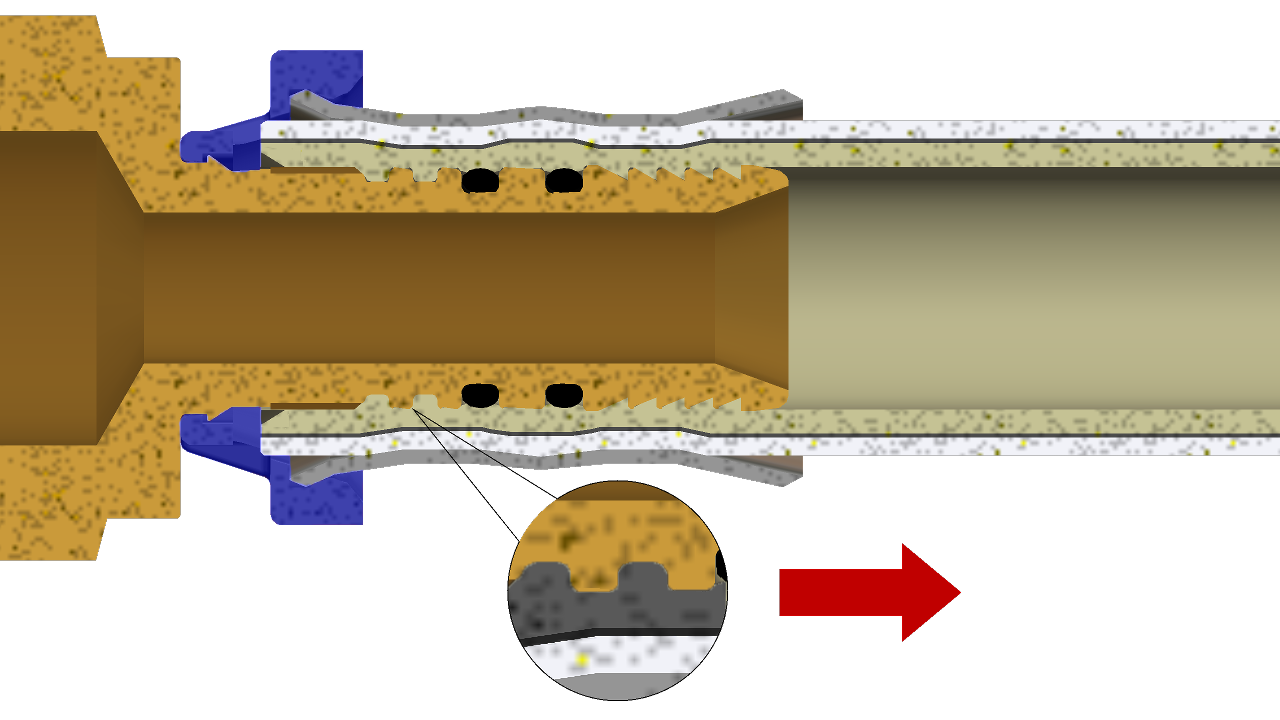

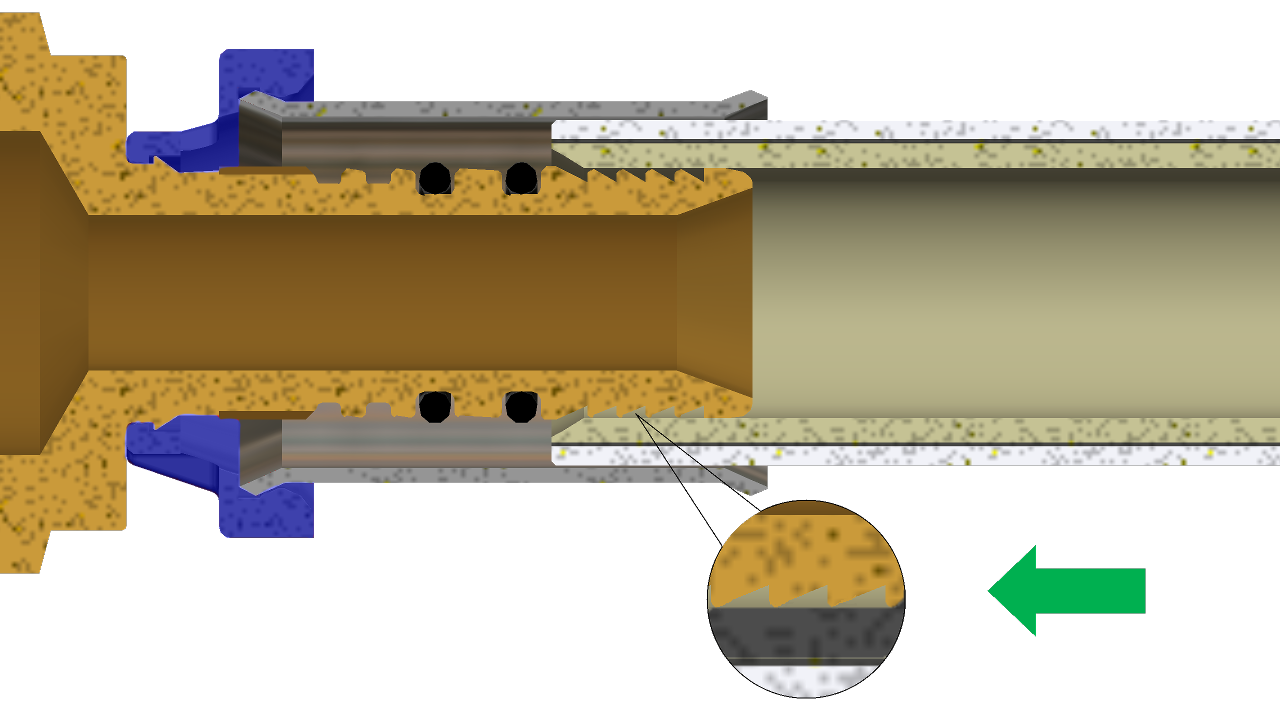

SPECIAL FITTINGS DESIGN

The fitting has been designed with a particular conformation so that all its elements

guarantee a series of advantages during installation and ensure an excellent seal.

FRONT

The front one is designed in order to facilitate the insertion of the fitting

into the pipe (easy push).

The special inclination of the corrugation has a double function:

• in one direction facilitates the fitting insertion

• in the opposite direction blocks the fitting

against pressure excess or water hammer.

REAR

The rear section has special grooves designed in order to guarantee the tightness between the plastic pipe and the metal fitting part.